IoT in machine usage monitoring with Tehotec

Read our reference case about our remote machine monitoring solution for Tehotec.

Challenge

Remote machine monitoring service without any galvanic connection to the machines

Industrial machines an equipment utilization rates are usually between 10-30% of effective working time. In many cases, even a moderate rise in the utilization rate of machine and equipment resources has a significant impact on the efficiency of companies’ operations and profitability. Tehotec wanted to create a remote machine monitoring service that would help their customers raise their efficiency and cut back unnecessary operations. To do this, they needed the right technology to gather machine usage data from industrial machinery and equipment. Their requirements were that the data needed to be collected without any galvanic connection to the machines, with no external power source and no connection to the company’s data network. The existing solutions had been wired systems that used the company’s data network to transfer data. This causes risks to both data and personal safety and adds plenty of costs to the entire system. In addition, wired systems are expensive and hard to install and use.

Approach

Testing a variety of features of Thingsee solution

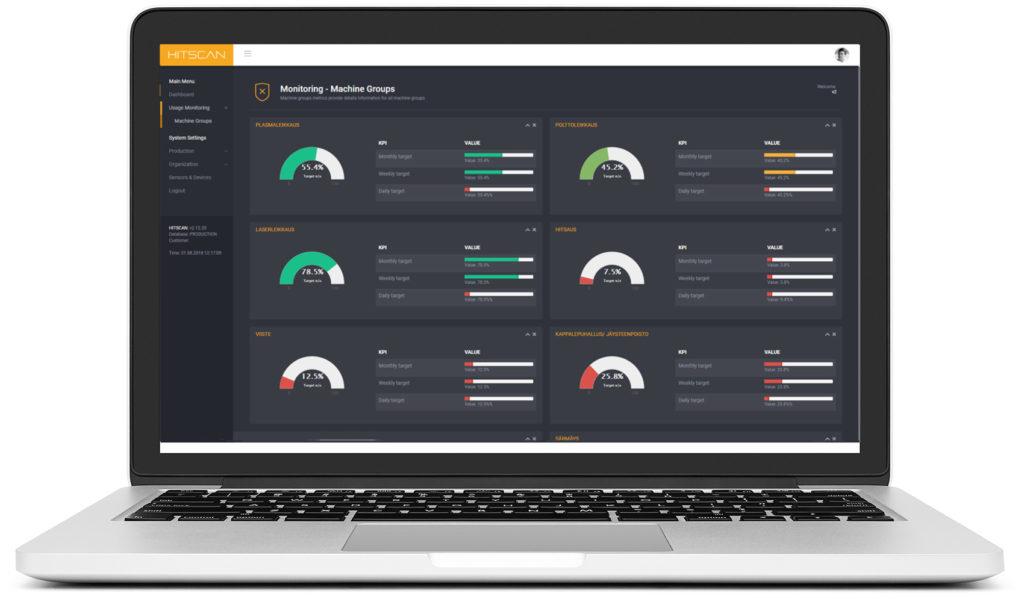

Tehotec had all the knowledge to improve business performance, and production and develop a visual interface. Haltian had the needed Thingsee IoT device platform, including sensors, gateways, connectivity, and device management. Tehotec reached out to Haltian, wanting to test the different features of Thingsee IoT sensors in machine usage monitoring. One of the first use cases was to measure vibration. Tehotec started testing with Thingsee ENVIRONMENT and Thingsee BEAM sensors and some features of the devices were developed according to the customer needs. For example, the light sensor in Thingsee ENVIRONMENT was optimized to fit Tehotec’s case. Starting with a small starter kit, Tehotec developed their HitScan Usage Time Monitoring service, a system that collects all the information in one, simple-to-use, graphical interface. Tehotec found creative ways to use Haltian’s existing sensors and gateways to reach its goals of delivering all the needed information to its customers.

Results

Wireless data collection, offering real-time insights

Now the usage time data is collected wireless and goes to Tehotec’s own system with no need for connection to the customer’s network. All the data is collected through a mesh network and is sent securely into the AWS cloud services database. With machine usage data, Tehotec can offer real-time insights and knowledge of any production process’s efficiency and possible bottlenecks, helping their customers save time and money. HitScan system is being used by several companies and the interest and reception of the system have been very good.

“Haltian has served as well and helped us as a starting company. We have gotten all the information we need to grow as a business and we are eager to continue our co-operation.”

Juho Lemponen, CEO, Tehotec

Get in touch

Want to discuss a new IoT solution for your business?

Book a meeting with Janne Kilpeläinen, VP sales, or contact him at janne.kilpeläinen@haltian.com