We bring your vision to life

Product innovation

We bring your vision to life with unparalleled expertise in innovative product creation. From concept to mass production, we support every phase of your product innovation journey. We help you realize and enhance your product vision with world-class product creation and resources. Our expertise covers the whole product lifecycle, from idea to mass production.

Driving product innovation

Get miniaturization expertise

Create the next great product

We are experts in creating wireless products. Let’s start the journey towards the next great thing.

Solve resource challenges

Extend your product creation team

Are you facing resource issues or want to outsource a particular project? We are here to help.

Expertise for any industry

Didn’t find your solution?

No worries. We offer product creation for any industry. We love a challenge, and we make impossible things easy.

INNOVATIVE SOLUTIONS FOR COMPLEX CHALLENGES

A holistic approach to product innovation

We specialize in turning your ideas into market-ready products through a seamless, end-to-end development process. Whether you’re enhancing an existing product or creating something entirely new, our tailored approach ensures that every solution meets your unique business needs. From design to production, we focus on innovation and quality to bring your vision to life.

End-to-end product development

Driving innovation

We transform ideas into market-ready products through a seamless, end-to-end development process, tailored to align with your business goals. Whether enhancing an existing product or creating something entirely new, we prioritize innovation and quality to ensure your vision becomes a reality that stands out in the market.

Start with concept creation

Our product development journey begins with a concept creation phase, establishing a strong foundation and clear direction for the device. This phase provides you with confidence that we fully understand your product vision and requirements, allowing us to make informed decisions right from the start.

Refine with prototyping

Through two to three prototype rounds, we continually refine and test the design, functionality, and performance, ensuring that the product not only meets but exceeds quality standards. This iterative process reduces risks and minimizes costly changes later, giving you a reliable, validated product design.

Ramping up the production

When the prototypes are validated, we move into the production ramp-up phase, where we set up efficient manufacturing processes and robust quality controls to prepare for mass production. By the end of this stage, you’ll have a first production batch ready, with scalable processes in place, allowing you to quickly respond to market demand and maximize your return on investment.

Solving challenges of product innovation

Turning ideas into reality

Creating user-friendly devices requires a strategic approach, and we guide you through every development stage to ensure resources are optimally used. Often, when we begin a project, the specifications aren’t fully defined — and this is totally fine for us. We always kick things off with a product concept creation phase lasting approximately 4–10 weeks, depending on the complexity of the product.

This step is essential for addressing open questions and uncertainties. During conceptualization, our team collaborates closely to create a comprehensive technical product concept. This concept combines usability and look & feel, with a preliminary mechanical structure designed to protect sensitive electronics from environmental stress.

To integrate the electronics effectively, we create a block diagram, draft the circuit board layout, and determine main component placements on the PCB. An architectural draft of the embedded software (firmware), including Operating System selection, is also developed to ensure the best compatibility with the selected electronic components. Additionally, we lay the groundwork for a smooth production testing phase, ensuring every element is considered for subsequent development stages.

We deliver critical assets during this phase, such as:

- Final product specification

- Non-functional product mockup

- Detailed BOM (Bill of Materials) and MVA (Manufacturer Value Add) estimate, meaning an estimated factory price for the product

- A comprehensive plan for mass production, covering labor and Non-Recurring Engineering (NRE) costs

With this thorough information package, you’ll have a solid basis for making informed business decisions, as well as a valuable tool for securing investor confidence or requesting a budget for the project. Whether you’re embracing new technology or refining an existing solution, we build with precision and innovation to bring your ideas to life.

End-to-end product innovation

Navigating through complexities

Our end-to-end approach means we handle everything from prototyping and testing to production and scaling. By collaborating closely with you throughout the process, we ensure your product is optimized for functionality, durability, and scalability.

Our comprehensive expertise covers every engineering domain, including Firmware (with Operating System selection), Electronics, Mechanical, Antenna, RF, Industrial Design, Product Validation, and Production Testing. Guided by our experienced Program Managers, we maintain transparent project management, giving you clear visibility into each phase.

Selecting a supplier strategy

Ensuring product and production quality

Together, we develop a Supplier Strategy tailored to your product’s unique needs, while supplier selections, such as Electronics Manufacturing Suppliers (EMS), are managed through a rigorous Request for Quotation (RFQ) process. With Haltian’s extensive experience in ramping up production across the globe we ensure efficient production setup and smooth scaling.

Our Quality Assurance processes cover both Product and Production Quality, as well as Regulatory Approvals Management, ensuring that each product meets the highest industry standards and performs reliably in the field. With a focus on quality and efficiency, we help bring your product to market faster, supporting its long-term success and scalability.

Some example industries we serve

Innovating imaging

Smart cameras

We develop hyper-spectral and action cameras designed for precise imaging and rugged environments. Whether for material analysis or extreme sports, we ensure high performance and durability, tailoring the hardware to meet your specific needs. Our solutions excel in capturing data and withstanding tough conditions.

Tracking solutions

GPS devices

We assist in the development of GPS devices tailored for smart mobility applications, from concept to production. With our expertise in tracking technology and energy-efficient design, we help you create reliable, high-performance systems for bicycles, e-scooters, and other personal transportation solutions.

Healthcare applications

Wearables

We specialize in developing lightweight, durable healthcare wearables for real-time monitoring. From sensor integration to ergonomic design, we ensure your product is comfortable, accurate, and reliable. Our custom-built wearables empower healthcare providers and patients with vital health data.

Estimate your price

Calculate your concept costs

Get a realistic idea of what your project will cost with our comprehensive tool. This step will ensure you’re prepared for the road ahead and ready to take action.

Essential parts of our offering

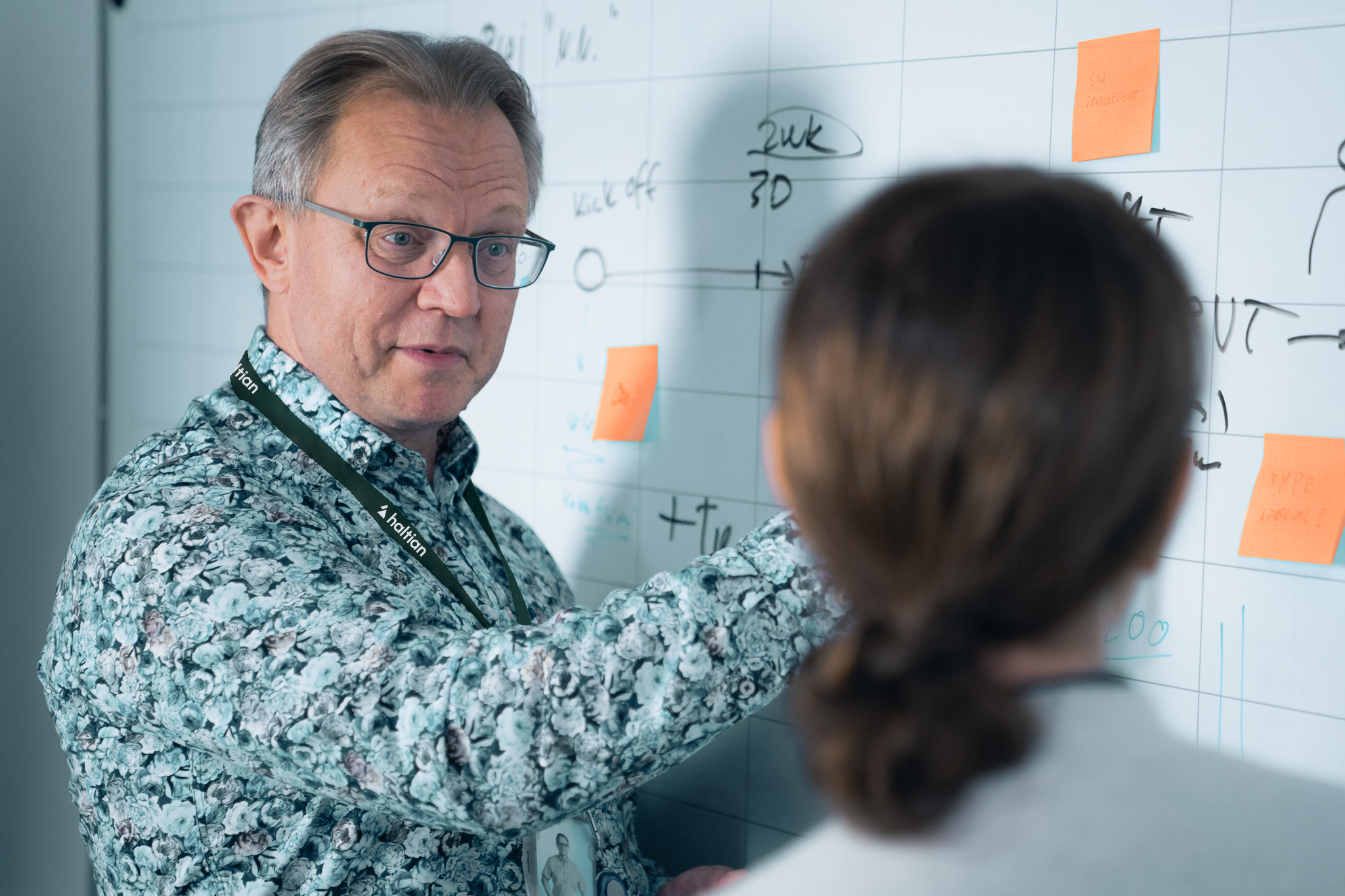

Project management

Effective project management is the backbone of successful product development. We take a structured yet flexible approach to managing complex projects, ensuring deadlines are met and resources are optimized. With a focus on minimizing risks and maximizing efficiency, our project managers guide your project from concept to completion with transparency and precision, allowing you to focus on the bigger picture.

hardware design

Our hardware design expertise combines innovation with practicality, delivering robust, high-performance solutions tailored to your product’s specific requirements. From initial concept and prototyping to final production, we focus on optimizing functionality, cost-efficiency, and manufacturability. Our team’s deep technical knowledge ensures that every component is designed with precision and built to withstand real-world conditions.

Software engineering

Our software engineering capabilities are designed to meet the most demanding product development needs. We offer full-stack development services, creating custom software that’s tailored to your product’s requirements. From system architecture to coding and testing, we ensure your software is built for long-term reliability, security, and scalability.

Our clients & selected partners

We are proud to collaborate with industry-leading clients and partners who trust us to deliver innovative, high-quality solutions. Their continued success is a testament to our expertise and commitment to excellence across a range of industries.

Customer story

Bringing the Wondershop Vision to Life with Haltian

We are all about turning bold ideas into tangible technology. Read our latest customer story on how we brought Wondershop’s vision to life.

Get in touch

Custom solutions specialist

Jarno Leskelä

jarno.leskela@haltian.com

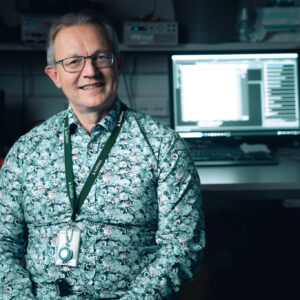

Custom solutions specialist

Jari Arvola

jari.arvola@haltian.com

You might be interested

Startups

Getting started with your product idea

We help startups turn product ideas into reality with our product creation services. From concept validation to prototypes, we guide you through the process, ensuring your product is ready for funding and market success.

Enterprises

Enhancing business operations

Our product innovation capabilities enable corporations to optimize operations and drive innovation. We help you scale efficiently, streamline processes, and stay competitive with high-performance, tailored solutions.

Any industry

Solutions for all industries

Our product development services adapt to any industry, from healthcare to consumer tech. We deliver custom solutions that meet the unique demands of your market, helping you innovate and succeed.