4 new product development stages explained

Product development of a smart device or a new IoT device is a highly sensitive process that always includes some balancing between creating a superb user experience, development costs, and time. Here are 4 new product development stages explained so that you can start planning the process of bringing your idea to life and a market-ready product.

Table of contents

- New product development as a user-experience-driven process

- 4 new product development stages

- Concept study

- Creating a prototype

- Productization

- Manufacturing, after-sales, and maintenance

- Other product development stages

- Final words: Well begun is half done

New product development should be a user-experience-driven process

When it comes to new product development, user experience should be the driving force behind everything since a working product with a bad user experience is not a working product at all. Nevertheless, other crucial factors in any new product development project are the costs and the schedule. To keep the development costs reasonable and the schedule in check at the same time, every design detail must be considered carefully at the beginning of the development process. Ignoring any fact can prevent meaningful use of the product and deliver the user a watered user experience. On the other hand, overblown requirements can result in higher technical complexity and cost. In the worst-case scenario, the result can be, for example, a bulky device with a too short battery lifetime, i.e. a poor user experience.

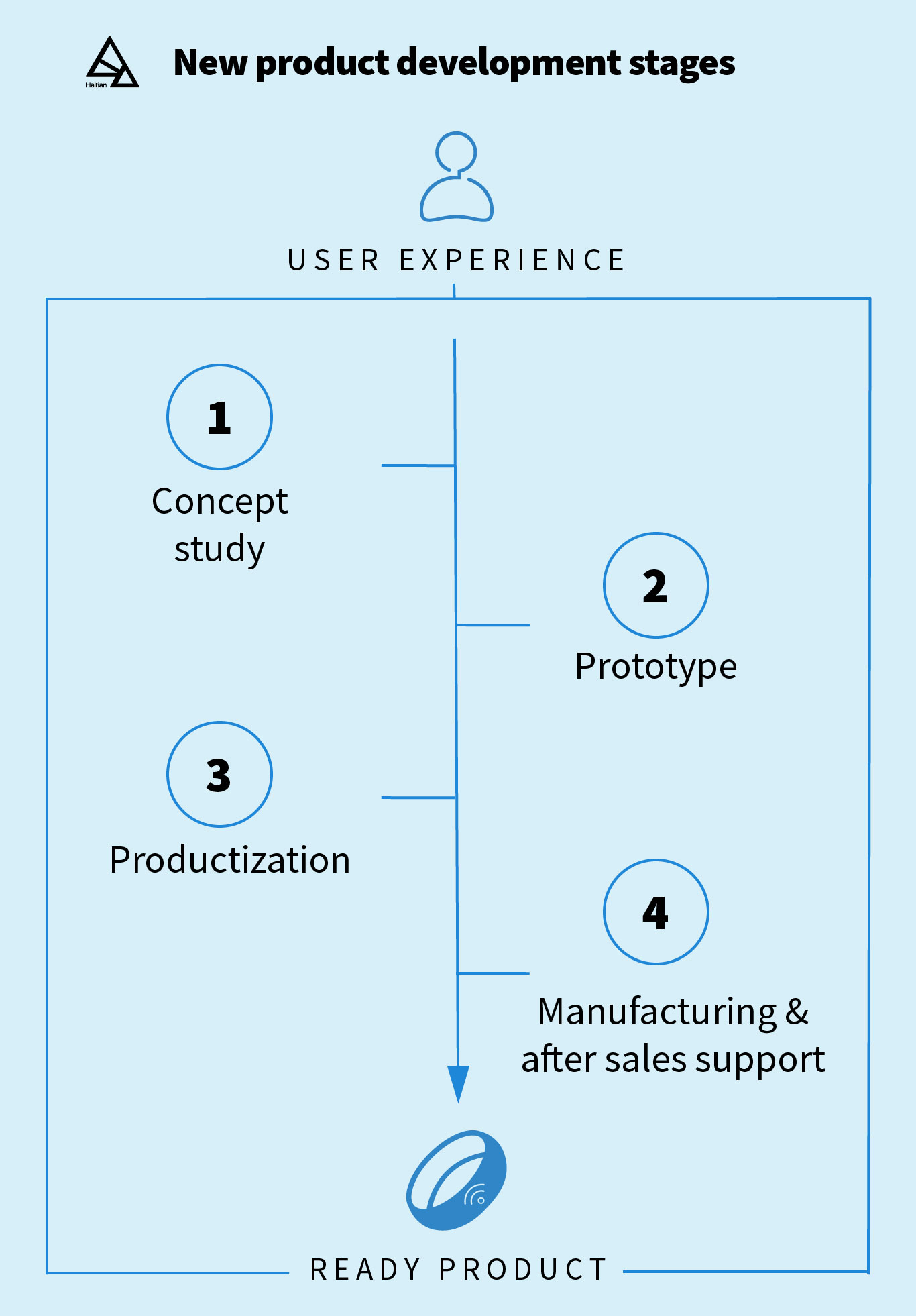

Not every new product development process is the same and the product development stages may vary depending on the maturity of the idea. Most commonly, new product development begins with a concept study, followed by creating a prototype, the actual productization, and finally, manufacturing and after-sales.

1. Concept study

A concept study is the first part of any product development project. It will give you the initial big picture of all the different stages of the development process and describe what problems the product will solve, how it will solve them, and what the product will feel like in use.

It can be said that the very soul of innovation lies in the concept study when all sweeping ideas and various possibilities are considered and a full product development plan is laid out.

A concept study is one of the most crucial steps in a new product development project, and it can be a key element in, for example, securing funding for a new product.

2. Creating a prototype

A ready product speaks louder than a thousand words and that is why creating a prototype is one of the most rewarding of the new product development phases. When you create a prototype, it’s the first time you get to hold an actual working device in your hands. The prototype is something you can show to investors and other stakeholders to, again, secure more funding and consolidate your idea.

The main purpose of the prototype is to help you make decisions concerning the product development and allow you to see possible improvements and changes you wish to make to the product. In addition, in the prototyping phase, things like an Engineering validation test is done to ensure that the basic unit performs to the design goals and specifications. A hardware prototype is also needed to develop the device software and test and develop the UX/UI design. In short, it’s safe to say that having the prototype is a huge stage in the new product development process!

3. Productization

The last of the new product development stages is the one that leads you to the final, ready product. Productization includes several stages, but here are some of them listed:

Building the Supply Chain

Once the prototyping is ready, it’s time to find the right partners needed for the correct materials, as well as partners needed for production. Building the supply chain means finding the different vendors, activities, and resources needed to create the product and getting it ready for mass production.

During the stage of building the supply chain, the Request for Quotation (RFQ) process begins. The RFQ is sent to the Electronics Manufacturing Services (EMS) partners and the production setup is started with them.

In this stage, good connections and experience count for a lot, as sourcing done wrong can mean extra costs and delays in the new product development project.

Product verification

Product verification is a multistep, important part of the new product development process. In this phase, the product is fully tested and verified against the regulated environment and reliability demands. The UX and UI of the product are tested as well as the functionality of the software.

When the product is fully tested, it can be safely released for mass production and out on the field. The more comprehensive the testing, the less you’ll get any surprises and returns on your device.

Once again, experience helps the product verification stage as an experienced partner will know which tests are necessary and help you avoid over-testing the product at the same time.

Production set-up

Once you have chosen your production partner, you’ll begin to set up the production line needed for mass production. The production line can be very simple or complex depending on the product, production volumes and the required testing to ensure the quality of the product.

Every single product is tested before going out to the customer to avoid any nasty surprises or returns.

Regulatory approvals and certifications

In this stage, all the documentation that is needed for the process is collected and produced. Special devices for type approval measurements are built and the needed software is developed for type approval testing purposes.

During the type approvals and certification stage, close collaboration is needed between the product development team and the type approval measurement laboratory so that that type approval process would go as fast as possible. Most product development partners have good connections to certification partners that can speed up the certification process. Usually, type approvals take between 4 and 10 weeks, which is important to consider when looking at the overall schedule of your new product development process.

4. Manufacturing, after-sales and maintenance

Finding the right manufacturing partner is an important part of the Supply Chain Building stage, and during the Productization stage, you will begin working with your manufacturing partner.

Where to manufacture your product?

It’s important to know that negotiations with a manufacturing partner are often a time-consuming process, but it’s vitally important to find the right manufacturing partner for your product. As we know, European products are often manufactured in China, either in mainland China or Taiwan, but manufacturing in Europe is also a good option. There are many factors to consider when choosing a manufacturing location, such as production volumes, the amount of manual work needed for the assembly of your product and the price of an individual product. Things such as sustainability and changing world situations are also important to consider. After the COVID pandemic travelling to Asia has gotten a lot harder and many companies are now wanting their manufacturing to move closer to their target market.

Good planning can help you narrow down the price differences between Asian and European manufacturing costs: if you have well-made Design for Manufacturing (DFM), Design for Assembly (DFA)and Design for Testing (DFT) to assembly and production costs of your product can be lower.

Ramping up your product

Ramping up a product is a big effort that requires seamless cooperation between the customer and manufacturing. At the same time, the sales and marketing of your product need to be working full steam ahead. Most startups don’t have the necessary recourses to work on both things, and at this stage, a product development partner can help you to get over the ramp-up stage smoothly. If you do decide to work with a new product development partner, after ramp-up, product development projects continue as support or maintenance for the product or solution.

Get to know Haltian new product development services

Other new product development stages

Here are some other terms you might run into in new product development:

Feasibility study

A feasibility study can be called a type of reality check: it’s an independent assessment of the practicality of the product, plan, or method. In the feasibility study we will answer questions like Do we have, or can we create technology to do his? Do we have the needed resources? Etc.

A feasibility study is not always necessary and is therefore not automatically always done as a part of the new product development project.

POC (Proof of concept)

POC can be built when you aren’t sure if your idea can work. The POC will not cover the entire system, but a small part of it and they’re usually built from ready, off-the-shelf components. POCs are only used inside your company to clarify the development direction, but sometimes you can also consider building a POC to get the seed-stage funding.

If needed, the POC is usually done between the feasibility study and the concept study.

MVP (Minimum Viable Product)

An MVP is a version of a product that has just enough features to stay viable. In other words, it’s not packed with all the features and only has the core functionality. The purpose of building an MVP is to get the minimum version of the product to the market and see if the product will have demand. If the product proves to have value for the customers, you can start making money right away from your first customers, i.e. the early adopters, and also fill your product with the features that were left out.

Final words: Well begun is half done

New product development stages are never the same from project to project, but one thing is for certain: the overall planning of all your product development stages should be done well from the beginning to ensure that your customers get a great user experience and that your new product development process stays on budget and schedule. Learn all about new product development from our comprehensive guide or learn what more you need to create your dream product: